This is a question we get many times from our customers. Especially common is a situation, in older installations, back to the times when multimode cable was cheaper than single mode, and inside buildings, and some last mile installations were planned so, that multimode cables were laid.

Answer is not that easy, to answer simply yes or no. Let’s delve in a details.

Definitions:

- SONET – Synchronous Optical Network

- SMF – SingleMode Fiber

- MMF – MultiMode Fiber

- LED – Light Emitting Diode

- DMD – Differential Mode Delay

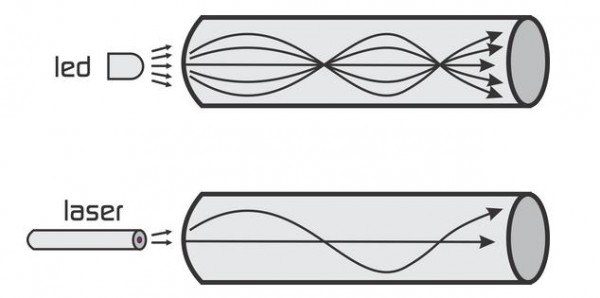

- Mode -

- light rays entering the fiber at the particular angle;

- paths of different length and transmission delays that travel through the cable.

SMF is using laser as a source for the light and therefore light beam is very concentrated. It allows higher bandwidth compared to MMF, while having greater transmission distance.

MMF is typically using LEDs for transmission of the optical signal. It is clear from the name, that it uses multiple modes of light at the same time. Entry angles differ for each mode of the light resulting in different speeds and distances that signal can travel.

Single mode vs Multimode

- It is possible to interconnect two devices using SMF interface at one end and MMF receiver at another one. But here, many depends also on devices. Like for example ,more sophisticated routers, like Huawei, Alcatel or Cisco while supporting that at physical layer, will not support it at TA. Problem is in DMD that may occur when two different modes are directly coupled. Degradation of the bandwidth also decreases the distance supported for transmission. Also, SMF transmitter should be calibrated in a way so the SMF signal would not overdrive MMF receiver.

Solution: Using the intermediate switch with SMF and MMF interfaces that is able to convert the signals is a good alternative.

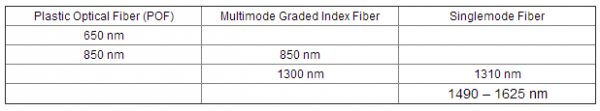

- If you use simple devices, such as video over fiber, or media converters, then it depends, what wavelength are used for your equipment. The trick here is that as we know, single-mode fibers used in telecommunications operate at 1310 or 1550 nm and require bit (now only a little bit) more expensive laser sources, and in older equipment MMF wavelength used were 850 nm.

And if you have this kind of transceivers, then it won’t work over your single mode cable. If you have a newer generation media converters, which use 1300 nm lasers, it will most likely work.

Table 1. Most common wavelengths (non WDM, CWDM or DWDM) used in optical transmission systems.

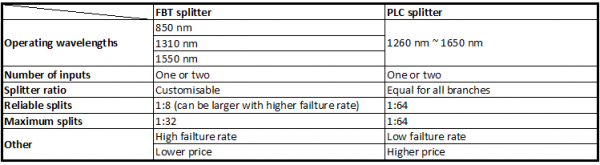

DK Photonics – www.dkphotonics.com specializes in designing and manufacturing of high quality optical passive components mainly for telecommunication, fiber sensor and fiber laser applications,such as PLC Splitter, WDM, FWDM, CWDM, DWDM, OADM,Optical Circulator, Isolator, PM Circulator, PM Isolator, Fused Coupler, Fused WDM, Collimator, Optical Switch and Polarization Maintaining Components, Pump Combiner, High power isolator, Patch Cord and all kinds of connectors.