In fiber-optic world of communication, wavelength-division multiplexing or WDM is an innovation which multiplexes various optical transporter signals onto a solitary optical fiber by utilizing distinctive wavelengths, that is the shades of the laser light. This system empowers bidirectional interchanges in more than one strand of fiber, and also increases the limits and domains of it. The term wavelength-division multiplexing is generally connected to an optical transporter, which is normally depicted by its wavelength, though recurrence division multiplexing is commonly applied to a radio bearer which is all the more of a frequently portrayer by recurrence. This is a simple convention since wavelength and recurrence convey a similar data.

How a WDM system works:

A WDM framework utilizes a multiplexer at the transmitter to combine the few signs and a demultiplexer at the collector to part them separated. Hence, WDM Mux and DeMux Modules are made to be used with the correct kind of fiber as it is conceivable to have a gadget that does both all the while, and can work as an optical add-drop multiplexer. The optical filtering gadgets utilized have ordinarily been etalons or to say, stable solid-state single-frequency Fabry–Pérot interferometers in the form of a thin-film-covered optical glass.

Need of WDM Multiplexing:

Since the physical fiber optic cabling is costly to actualize for every single company independently, its ability development by utilizing a Wave Division Multiplexing (WDM) is the need of the hour. WDM innovation was created to extend limits of single fiber systems can give. A WDM framework utilizes a Multiplexer at the transmitter to join a few wavelengths together; thus each one conveys diverse flag and signals via a demultiplexer at the recipient to make them separated. Both Mux and Demux are latent parts of the circuit, as their requirement of power is nil.

Types of WDM available:

These days there are a few sorts of institutionalized WDM in availibility:

- General WDM, for example, 980/1550 WDM, 1310/1550 WDM.

- CWDM incorporates CWDM mux/demux module and CWDM OADM module. The normal setup of CWDM mux/demux module is 2CH, 4CH, 8CH, 16CH, 18CH CWDM mux/demux module. Single fiber or double fiber association for CWDM Mux/demux are accessible.

- DWDM incorporates 50GHz, 100GHz, 200GHz DWDM mux/demux module and DWDM OADM module. The normal arrangement is 2CH, 4CH, 8CH, 16 CH, 32CH, 40CH channels.

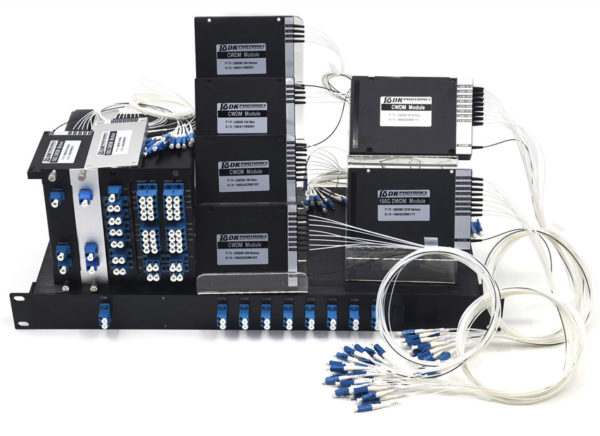

- They are accessible as Plastic ABS module tape, 19'' rack mountable box or standard LGX box. What's more, regardless of what sort of connectors, as FC, ST, SC, LC and so on, all is available on DK Photonics, and they additionally can blend connector on one gadget. DK Photonics Technology Limited is one of the main organizations in outlining and assembling of fantastic optical inactive parts primarily for media transmission, fiber sensor and fiber laser applications. Headquarter and manufacturing plant is situated in Shenzhen of China. Savvy, best quality and best administration are forever their objective. So if you have any requirement regarding the WDM or any of the devises based on it, DK Photonics is the reliable and trusted brand!