The

2015 Ringier Technology Innovation Awards - Laser Industry is now open for

applications up until January 4, 2015.

Now

in its second year, the Awards consist of six categories: Lasers, Laser Systems for Production

Engineering (Laser Cutting Systems, Laser Engraving Systems, Laser Marking

Systems, and Laser Welding Systems), Laser System Components, System

Peripherals of Laser Production Engineering, Optical Materials and Components,

and 3D Printing. Only new products and solutions launched during 2013-2015 in

the China market are eligible to enter the Awards selection process.

Following

the entry and nomination stage, online peer voting and expert judging will take

place January 9-25, 2015. Industry experts, including Dichen Li, Ph.D.,

Changjiang Professor, Xi'an Jiaotong University; Xiahui Tang, Professor,

National Engineering Research Center For Laser Processing; Youliang Wang,

Chairman, Laser Processing Committee of China Optical Society; Xiao Zhu,

Chairman, Wuhan Laser Association of Optics Valley of China; and Qingmao Zhang,

Vice Chairman, Laser Processing Committee of China Optical Society, will be

among the independent panel of judges. Winners will be announced at the Awards

ceremony on March 18, 2015, to coincide with Laser World of PHOTONICS 2015 in

Shanghai, when all the winners, judges, industry professionals, and media will

be present.

Organized

by Industrial Laser Solutions China, Ringier Trade Media, and supported by

Industrial Laser Solutions, these Awards are presented to a select group of

innovators each year in China. The purpose of the Awards is to encourage,

acknowledge, and reward those individuals and companies who have introduced and

developed a new idea, a new methodology, a new product or a new technology for

manufacturing production efficiency, cost-effectiveness, and user convenience,

which might result in energy saving and more responsible clean manufacturing in

the laser industry.

The

Ringier Technology Industry Awards Series have been established since 2006 and

cover nine different industries. They are recognized as being the most honest,

transparent, and fairest of such Industry Awards in China. Nominations are open

to all and the final selections are made by the panel of independent judges

based solely on merit.

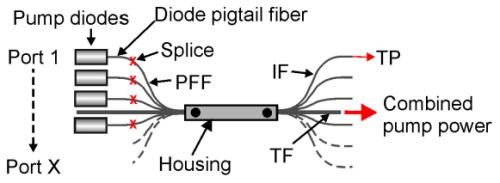

DK

Photonics – www.dkphotonics.com specializes

in designing and manufacturing of high quality optical passive components mainly

for fiber laser applications such

as 1064nm high power isolator, Cladding

Power Stripper, Multimode High Power Isolator, pump combiner,1064nm Band-pass

Filter,(6+1)X1 Pump and Signal Combiner, PM Circulator, PM Isolator, optical

Coupler. More information, please contact us.